Products

Products

Contact Us

WhatsApp: +1 2157069183

Cell: +86 13589651319, +86 13295392319

WeChat: 13589651319,13295392319

Tel: +86 539 6261319

Email: jd319@jindesic.com

Address: Economic Development Zone, Linshu, Linyi, Shandong, 276700 China

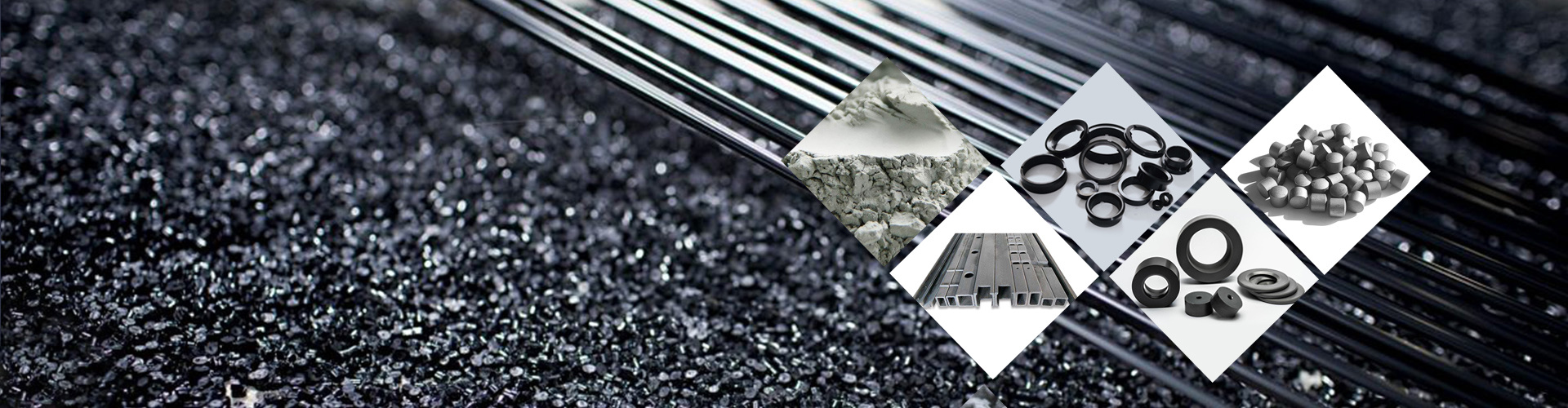

Made by wet grinding, the powder has high purity, narrow particle size distribution, good flowability, and strong stability.

INQUIRYSilicon carbide is used as the negative electrode material.

Silicon carbide anodes have a higher specific capacity, allowing them to store more lithium ions and achieve high energy density in batteries.

INQUIRYSilicon carbide bearing sleeve

It can be applied not only in industries such as petroleum, chemical, automotive, military, and papermaking, but also in food, pharmaceuticals, and nuclear industries.

INQUIRYFoamed ceramics using silicon carbide

Foamed ceramic insulation boards are made from main raw materials such as clay tailings, ceramic fragments, and adulterants, with silicon carbide added primarily for foaming purposes. They are formed into high porosity closed-cell ceramic materials through high-temperature roasting. The silicon carbide micro powder produced by Jinde has a uniform color and reasonable particle size distribution, making it suitable for different product formulations and production processes. The addition ratio is 0.3%-0.5%, resulting in uniform foaming pores and good permeability.

INQUIRYCustom non-pressure sintered silicon carbide

The manufacturing of high tensile strength silicon carbide high-temperature resistant ceramic special-shaped parts is a highly technical process.

INQUIRYSilicon carbide for ceramic membranes

Silicon carbide ceramic membranes have high chemical stability, good thermal shock resistance, strong hydrophilicity, large membrane flux, high mechanical strength, concentrated pore size distribution, and a relatively good pore structure gradient.

INQUIRYSilicon carbide for foam ceramics

Silicon carbide (SiC) foam ceramic filters have excellent strength, high-temperature impact resistance, and chemical corrosion resistance. They can be used at temperatures up to 1500°C and effectively filter impurities and non-metallic inclusions from molten metals, while also improving gas emissions during the flow and solidification processes of metals. Applications include molten metal filtration, high-temperature flue gas treatment, catalyst carriers, solid heat exchangers, and special fillers.

INQUIRYNon-stick pans use silicon carbide micro powder.

A non-stick pot coating made of silicon carbide micropowder has been launched, which is heat-resistant up to 1800 degrees, more corrosion-resistant, non-toxic, healthy, and environmentally friendly. In the non-stick pot coating, silicon carbide micropowder can form a hard protective layer.

INQUIRYSilicon carbide for semiconductors

Silicon carbide has gradually become a representative of third-generation semiconductor materials due to its advantages in bandgap width, dielectric constant, thermal conductivity, and maximum operating temperature.

INQUIRYDPF special silicon carbide micro powder

The diesel particulate filter (DPF) is made from high-purity silicon carbide micropowder that has been specially processed and purified. It is produced by mixing according to a formula, refining the mud, sedimentation, and then forming and firing.

INQUIRYMicrochannel reactor ceramic plate

Precision machined, resistant to various chemical corrosion, suitable for use in systems containing hydrofluoric acid, strong alkalis, and high temperatures.

INQUIRYSilicon carbide for abrasives and tools

Silicon carbide used for abrasives and tools mainly comes in various models and specifications such as 8#-6000#, including black and green silicon carbide granules and micro powders.

INQUIRYSilicon carbide for thermal insulation materials

Insulation materials generally refer to materials with a thermal conductivity of less than or equal to 0.12, including insulation boards, nano-micro porous insulation boards, etc.

INQUIRYSilicon carbide for fiberglass

Silicon carbide used in fiberglass has advantages such as high temperature resistance, corrosion resistance, high hardness, lightweight high strength, and good thermal conductivity. It is suitable for manufacturing high-temperature equipment, pipelines, and chemical containers.

INQUIRYCustomized reaction-sintered silicon carbide

Widely used in metallurgy, chemical industry, raw material processing, transportation of highly corrosive and wear-resistant fluid substances, powder processing, desulfurization and dust removal devices in thermal power plants and large boilers, as well as heating devices in tunnel kilns, shuttle kilns, and roller kilns.

INQUIRYSilicon carbide for sandblasting

Matte treatment of the surface of steel, steel pipes, and stainless steel products, with sandblasting rust removal before spraying.

INQUIRYRoller rods made of silicon carbide

Widely used in applications such as roller kilns, tunnel kilns, electric furnace wire kilns, silicon carbide rod electric kilns, and natural gas kilns.

INQUIRYSilicon carbide for coated abrasives

Silicon carbide used in coated abrasives is a commonly used abrasive material, such as sand belts, sand cloths, and sandpapers. Silicon carbide has advantages such as high hardness, good wear resistance, and strong chemical stability, which can effectively improve the grinding efficiency and processing quality of abrasives.

INQUIRYHigh hardness, long lifespan, wear-resistant and corrosion-resistant, widely used in sand mill manufacturers.

INQUIRYMetallic silicon (crystalline silicon or industrial silicon)

Metallic silicon, also known as crystalline silicon or industrial silicon, is a product smelted from quartz and coke in an electric furnace.

INQUIRYWelcome your message consultation