Products

Contact Us

WhatsApp: +1 2157069183

Cell: +86 13589651319, +86 13295392319

WeChat: 13589651319,13295392319

Tel: +86 539 6261319

Email: jd319@jindesic.com

Address: Economic Development Zone, Linshu, Linyi, Shandong, 276700 China

Foamed ceramics using silicon carbide

Classification:

Tag:

Introduction to Silicon Carbide for Foamed Ceramics

Silicon carbide is produced by high-temperature smelting of silica and anthracite or petroleum coke in an electric furnace at 1800℃-2400℃ for 50-200 hours.

Silicon carbide is classified by color into black silicon carbide and green silicon carbide. Black silicon carbide is mainly produced from anthracite and silica (quartz sand) at high temperatures. Green silicon carbide is mainly produced from petroleum coke and silica with a small amount of sodium chloride added, resulting in a dark green color.

Processing Technology and Equipment for Silicon Carbide Micro Powder for Foamed Ceramics

The raw silicon carbide blocks are crushed by a jaw crusher and then ground into coarse particles of 5mm-0 by a crusher. These are then milled in a ball mill and screened to produce fine particles of 60#-0. After magnetic separation, they undergo further processing through Raymond mills, air flow mills, etc., to produce silicon carbide particles that reach micro powder sizes of 30um to 5um, followed by air classification and screening processes, gradually producing a series of silicon carbide micro powder grades that meet industry standards or customer requirements.

Applications and Advantages of Silicon Carbide Micro Powder for Foamed Ceramics

Foamed ceramics are materials with porous properties formed by mixing one or more ceramic raw materials, foaming agents, binders, etc., and then heating to create pores, expand, and harden. Due to their porous nature, foamed ceramics have advantages such as lightweight, sound insulation, thermal insulation, and water absorption, and are widely used in construction materials, filtration materials, heat dissipation materials, and other fields.

Application of Silicon Carbide in Foamed Ceramics

1. As a Foaming Agent

In the production process of foamed ceramics, an appropriate amount of foaming agent needs to be added to create bubbles, thus forming a porous material. Silicon carbide is a good foaming agent that can release a large amount of gas during the production process, helping to form bubbles.

2. Improving the Performance of Ceramic Materials

Silicon carbide has excellent properties such as high hardness and high heat resistance, which can provide better performance for foamed ceramics. For example, adding a certain amount of silicon carbide during the preparation of ceramics can improve the wear and corrosion resistance of the ceramics, extending their service life.

3. Changing the Color and Texture of Ceramic Materials

Due to the black, gray, and other colors of silicon carbide, it can change the color and texture of ceramics during production. For example, adding a certain amount of silicon carbide during the preparation of ceramics can result in black or gray colors and textures, enhancing the aesthetic appeal of the ceramics.

Advantages of Silicon Carbide in Foamed Ceramics

1. High Hardness and Good Heat Resistance

Silicon carbide has excellent properties such as high hardness and high heat resistance, providing better performance in foamed ceramics.

2. Beneficial for the Production Process

Adding a certain amount of silicon carbide can improve material performance, enhance product quality, while also shortening the production process and reducing production costs.

3. Enhancing the Aesthetic Appeal of Ceramics

Silicon carbide has colors such as black and gray, which can change the color and texture of ceramics during production, increasing the aesthetic appeal of the ceramics.

Application Cases of Silicon Carbide in Foamed Ceramic Production

1. Foamed Ceramic Insulation Materials

Foamed ceramic insulation materials are made by mixing clay, coal powder, foaming agents, and other materials, then sintering at high temperatures, providing good thermal insulation properties. Adding a certain amount of silicon carbide during production can increase the hardness and heat resistance of the material.

2. Filter Elements

Foamed ceramic filter elements are filters used in water treatment, electronics, food, pharmaceuticals, and other fields, providing filtration and separation effects for flowing liquids. Adding a certain amount of silicon carbide during the production of filter elements can increase their wear resistance and stability.

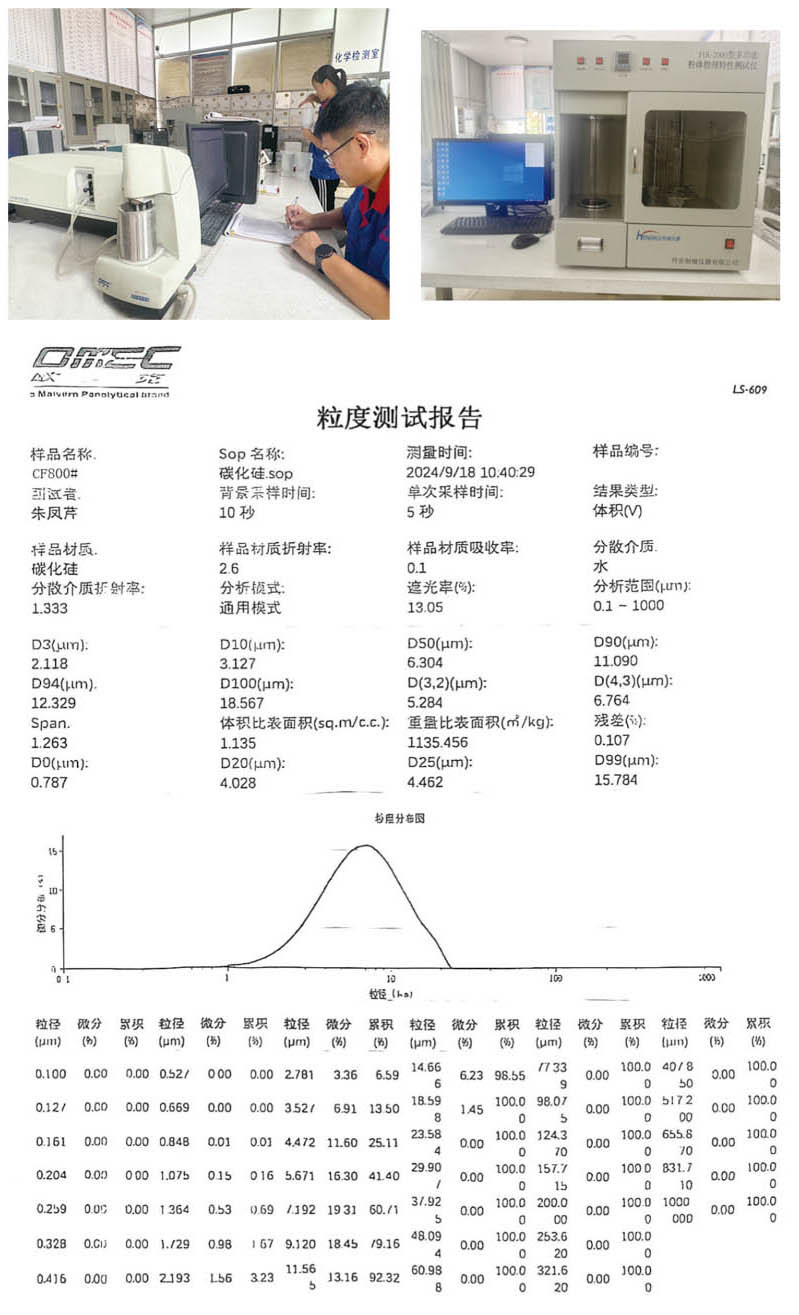

Silicon Carbide Testing Equipment and Reports for Foamed Ceramics:

Packaging

Product production

Product Certification

Faq

Can I visit your factory?

Welcome to our factory. Please contact us first. With your schedule, we will provide you with the necessary services.

Do you have any samples?

We will provide free samples or make samples based on your color samples.

Do you accept small orders?

Don't worry. Please feel free to contact us at any time. In order to obtain more orders and provide our customers with more conveners, we accept small orders.

When can I get the quotation?

We usually provide you with a quotation within 24 hours after receiving your inquiry. If you urgently need a quote. Please call us or let us know in your email so that we can prioritize your inquiry.

More products

Welcome your message consultation