Products

Products

Contact Us

WhatsApp: +1 2157069183

Cell: +86 13589651319, +86 13295392319

WeChat: 13589651319,13295392319

Tel: +86 539 6261319

Email: jd319@jindesic.com

Address: Economic Development Zone, Linshu, Linyi, Shandong, 276700 China

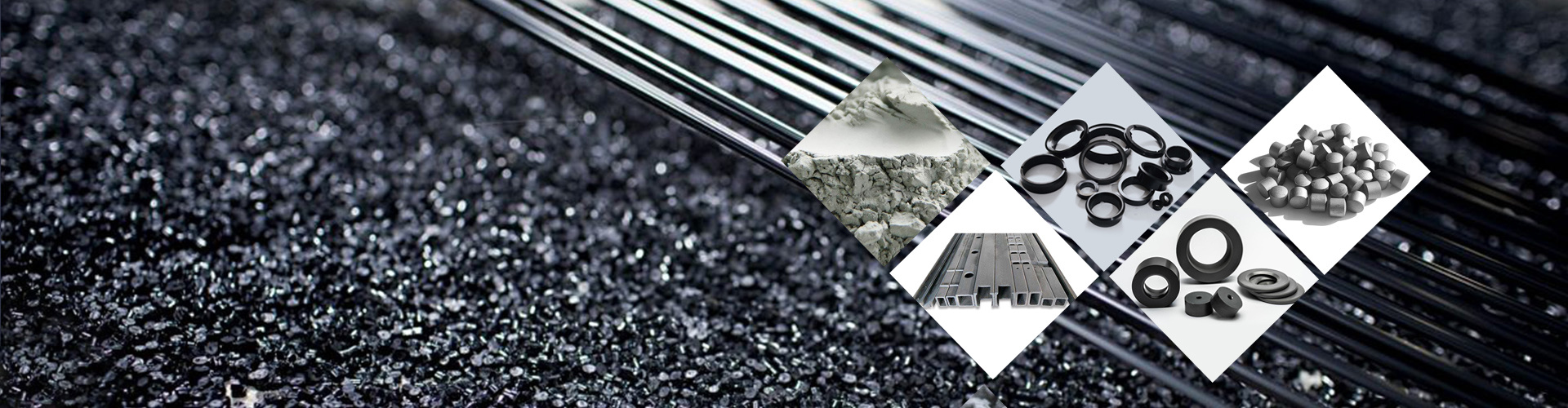

Foamed ceramics using silicon carbide

Foamed ceramic insulation boards are made from main raw materials such as clay tailings, ceramic fragments, and adulterants, with silicon carbide added primarily for foaming purposes. They are formed into high porosity closed-cell ceramic materials through high-temperature roasting. The silicon carbide micro powder produced by Jinde has a uniform color and reasonable particle size distribution, making it suitable for different product formulations and production processes. The addition ratio is 0.3%-0.5%, resulting in uniform foaming pores and good permeability.

INQUIRYSilicon carbide for ceramic membranes

Silicon carbide ceramic membranes have high chemical stability, good thermal shock resistance, strong hydrophilicity, large membrane flux, high mechanical strength, concentrated pore size distribution, and a relatively good pore structure gradient.

INQUIRYSilicon carbide for foam ceramics

Silicon carbide (SiC) foam ceramic filters have excellent strength, high-temperature impact resistance, and chemical corrosion resistance. They can be used at temperatures up to 1500°C and effectively filter impurities and non-metallic inclusions from molten metals, while also improving gas emissions during the flow and solidification processes of metals. Applications include molten metal filtration, high-temperature flue gas treatment, catalyst carriers, solid heat exchangers, and special fillers.

INQUIRYWelcome your message consultation