Products

Contact Us

E-mail:jd319@jindesic.com

Telephone:+86-539-6261319

Address:Economic Development Zone, Linshu County, Shandong Province

Silicon carbide for ceramics

Classification:

Tag:

Silicon carbide is produced by smelting silica and anthracite or petroleum coke in an electric furnace at 1800℃-2400℃ for 50-200 hours.

Silicon carbide has various crystal forms, with the alpha (α) phase of silicon carbide, also known as polycrystalline silicon carbide, being mainly used for abrasives and refractory materials.

Due to its unique silicon-carbon structure, silicon carbide has a very stable chemical structure. It is commonly used in reaction-sintered ceramics, pressureless sintered ceramics, and recrystallized silicon carbide ceramics.

(1) Silicon carbide for reaction-sintered ceramics

Mainly uses green silicon carbide GCF240#, GCF1200# (slurry forming) and GCF90#, GCF150#, GCF180#, GCF240# (extrusion forming), GCW10 and GCW14 (press forming) specifications.

Using air flow grinding processing technology, it has advantages such as high purity, good particle shape, strong fluidity, and reasonable particle size distribution, mainly applied in the production of roller rods, beams, kiln furniture, seals, grinding barrels, crystal boats, and crystal trays, etc. of silicon carbide ceramic products.

(2) Silicon carbide for pressureless sintered ceramics

Mainly uses green silicon carbide ultrafine powder GCW0.5 products. The production process adopts wet grinding, which has advantages such as high purity, narrow particle size distribution, good fluidity, and strong stability.

Widely used in the production of seals, heat exchange tubes, bulletproof equipment (bulletproof plates), silicon carbide 3D mobile phone back glass thermal bending molds, etc. of silicon carbide ceramic products, with characteristics of high density, high hardness, wear resistance, and corrosion resistance.

(3) Silicon carbide for recrystallized ceramics

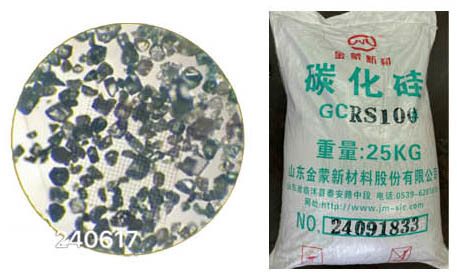

Mainly uses green silicon carbide RS07 and RS100 products. The production process adopts air flow grinding shaping and grinding modification, which has advantages such as high purity, narrow particle size distribution, high bulk density, good fluidity, and strong stability.

Mainly applied in the production of daily porcelain, electrical porcelain, sanitary porcelain, etc. for high-temperature kiln roller rods, beams, shelves, crucibles, etc. of recrystallized ceramic products.

Processing technology and equipment for silicon carbide ceramics

During the smelting process of silicon carbide, there will be a small amount of magnetic substances, free silicon, free carbon, and other impurities, which need to be purified by chemical methods to remove impurities, magnetic substances, free silicon, and free carbon, requiring sulfuric acid washing and sodium hydroxide washing.

The processing equipment for silicon carbide for silicon carbide ceramics mainly includes air flow mills, wet grinders, etc.

Testing equipment

The main testing instruments for silicon carbide include Malvern laser particle size analyzers, magnetic substance analyzers, and bulk density testers.

Packaging

The packaging of silicon carbide products for silicon carbide ceramics generally has three packaging methods: small bags with pallets, small bags with ton bags, and ton bags with pallets.