Products

Contact Us

E-mail:jd319@jindesic.com

Telephone:+86-539-6261319

Address:Economic Development Zone, Linshu County, Shandong Province

Non-stick pans use silicon carbide micro powder.

Classification:

Tag:

Silicon carbide is produced by high-temperature smelting of silica and anthracite or petroleum coke in an electric furnace at 1800℃-2400℃ for 50-200 hours.

Silicon carbide has various crystal forms, with the alpha (α) phase of silicon carbide, also known as polycrystalline silicon carbide, being mainly used for abrasives and refractory materials.

Due to its unique silicon-carbon structure, silicon carbide has a very stable chemical structure. It is resistant to oxidation, acids and bases, and corrosion, with a hardness second only to diamond (internationally, diamond is rated at 10 on the Mohs scale, while silicon carbide has a Mohs hardness of 9.3-9.5).

It can be used for abrasives, grinding wheels, sandpaper, polishing, grinding, cutting, silicon carbide structural ceramics, refractory materials, etc.

Silicon carbide is classified by color into black silicon carbide and green silicon carbide. Black silicon carbide is mainly produced from anthracite and silica (quartz sand) at high temperatures. Green silicon carbide is mainly produced from petroleum coke and silica with a small amount of sodium chloride added, resulting in a dark green color.

Silicon carbide raw blocks are crushed by a jaw crusher and then ground into coarse particles of 5mm-0. These particles are further processed through ball mills, Raymond mills, and air flow mills to achieve silicon carbide particles ranging from 63um to 5um. This type of silicon carbide powder undergoes purification through acid washing, alkali washing, and magnetic separation, followed by screening, air classification, overflow classification, and sedimentation classification, gradually producing a series of silicon carbide micro-powder grades that meet international or enterprise standards.

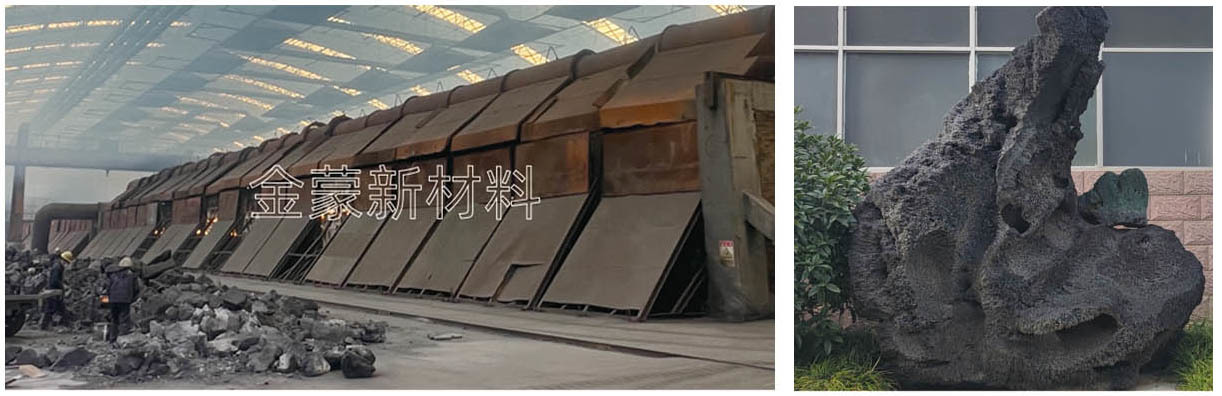

Silicon carbide micro-powder processing equipment

During the smelting process of silicon carbide, there may be a small amount of magnetic substances, free silicon, free carbon, and other impurities, which need to be removed through chemical purification methods, including sulfuric acid washing and sodium hydroxide alkali washing.

Jinmeng New Materials Company has advanced grinding equipment including dry ball mills, wet ball mills, Raymond machines for particle size grinding, micro-powder grinding Raymond machines, air flow grinding machines, ultra-fine powder grinding production lines, and particle shaping machines. It also has purification production lines, air classifiers, overflow classification production lines, flash drying machines, large automated mixing machines, and automated packaging equipment, which can meet the special requirements of different customers regarding product particle shape, particle size distribution, and process requirements.

Silicon carbide micro-powder applications

Silicon carbide micro-powder can be used for surface polishing of objects (such as mobile phone back panels and screens), grinding, cutting, sandpaper, silicon carbide ceramics, silicon carbide ceramic substrates, thermal conductive materials, insulation materials, non-stick coatings, foam ceramics, foamed ceramics, unpressed silicon carbide ceramics, recrystallized silicon carbide ceramics, reaction-sintered silicon carbide ceramics, automotive three-way catalysts (DPF), silicon carbide ceramic membranes, and many other industries and fields including 3D printing materials.

Product delivery