Products

Contact Us

WhatsApp: +1 2157069183

Cell: +86 13589651319, +86 13295392319

WeChat: 13589651319,13295392319

Tel: +86 539 6261319

Email: jd319@jindesic.com

Address: Economic Development Zone, Linshu, Linyi, Shandong, 276700 China

refractory materials

Classification:

Tag:

Silicon carbide is produced by smelting silica and anthracite or petroleum coke in an electric furnace at temperatures between 1800℃ and 2400℃ for 50 to 200 hours.

During the smelting process of silicon carbide, due to the open-air and graphite core conductive heating method, the temperature of the furnace core is the highest, gradually decreasing from the inside to the outside. The quality of silicon carbide generated from the inside to the outside also decreases, with the inner level having a silicon carbide content of over 98%, followed by the second level with a content between 95% and 85%. Further out is the third level with a content between 80% and 65%, and the outermost layer is yellow skin, with a content of about 40%. The second and third levels of silicon carbide have low silicon carbide content, low hardness, and are easy to decompose, making them suitable for use as refractory materials and deoxidizers for increasing silicon during steelmaking.

Applications of silicon carbide in refractory materials:

The main applications of silicon carbide in refractory materials include silicon carbide refractory bricks, silicon carbide shelf plates, gun mud additives, silicon carbide crucibles, iron trench materials, three major components of continuous casting, and silicon carbide refractory material products.

The main models of silicon carbide used for refractory materials and deoxidizers are:

Silicon carbide content: 98%, 88%-90%, 68%-78%.

Specifications include: 5-1mm, 0-1mm, 200#-0, 325#-0, etc.

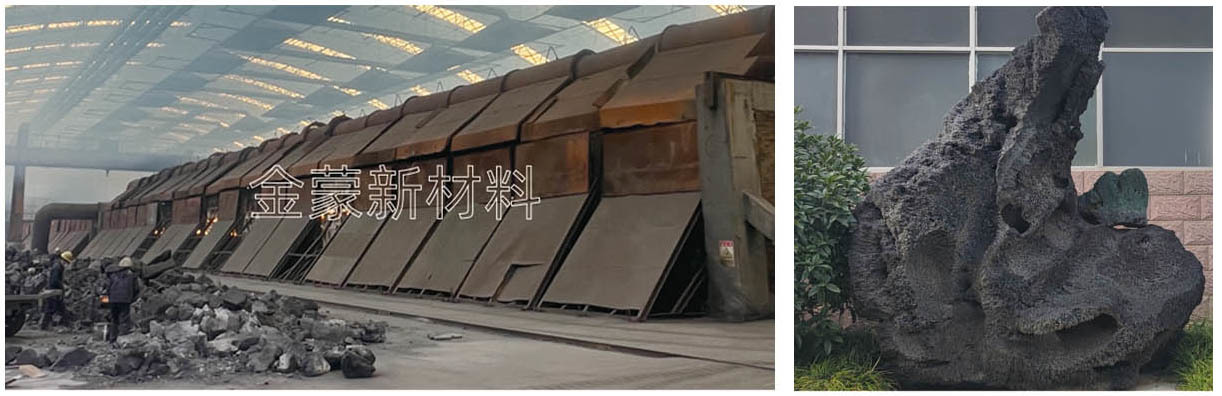

Packaging display of silicon carbide used as a deoxidizer in refractory materials:

Product production

Product Certification

Faq

Can I visit your factory?

Welcome to our factory. Please contact us first. With your schedule, we will provide you with the necessary services.

Do you have any samples?

We will provide free samples or make samples based on your color samples.

Do you accept small orders?

Don't worry. Please feel free to contact us at any time. In order to obtain more orders and provide our customers with more conveners, we accept small orders.

When can I get the quotation?

We usually provide you with a quotation within 24 hours after receiving your inquiry. If you urgently need a quote. Please call us or let us know in your email so that we can prioritize your inquiry.

More products

Welcome your message consultation