Polishing methods for silicon carbide ceramic products

2024-12-12

The commonly used polishing methods for silicon carbide ceramic products are as follows:

1. Mechanical polishing: Mechanical polishing is a method that relies on cutting and plastic deformation of the material surface to remove the protruding parts after polishing to achieve a smooth surface. It generally uses oilstone strips, wool wheels, sandpaper, etc., mainly operated manually. For special parts like the surface of rotating bodies, auxiliary tools such as turntables can be used. For surfaces with high quality requirements, ultra-precision polishing can be adopted. Ultra-precision polishing uses specially made grinding tools, which are pressed tightly against the surface of the workpiece in a grinding liquid containing abrasives, performing high-speed rotational motion. This technology can achieve a surface roughness of Ra0.008μm, which is the highest among various polishing methods. This method is commonly used for optical lens molds.

2. Chemical polishing: Chemical polishing allows the micro-protruding parts of the material to dissolve preferentially in a chemical medium compared to the recessed parts, resulting in a smooth surface. The main advantage of this method is that it does not require complex equipment, can polish complex-shaped workpieces, and can polish many workpieces simultaneously, making it highly efficient. The core issue of chemical polishing is the formulation of the polishing solution. The surface roughness obtained from chemical polishing is generally several tens of micrometers.

3. Electrolytic polishing: The basic principle of electrolytic polishing is the same as that of chemical polishing, which relies on the selective dissolution of the small protruding parts of the material surface to make the surface smooth. Compared to chemical polishing, it can eliminate the effects of cathodic reactions, resulting in better effects.

The electrochemical polishing process is divided into two steps:

(1) Macroscopic leveling, where the dissolved products diffuse into the electrolyte, and the geometric roughness of the material surface decreases, Ra>1μm.

(2) Microscopic leveling, anodic polarization, where the surface brightness increases, Ra<1μm.

4. Ultrasonic polishing: The workpiece is placed in an abrasive suspension and subjected to an ultrasonic field, relying on the oscillation effect of the ultrasound to grind and polish the abrasive on the surface of the workpiece. Ultrasonic processing has low macroscopic force and will not cause deformation of the workpiece, but the production and installation of the tooling are relatively difficult. Ultrasonic processing can be combined with chemical or electrochemical methods. Based on solution corrosion and electrolysis, ultrasonic vibration can be applied to stir the solution, allowing the dissolved products on the workpiece surface to detach, and the corrosion or electrolyte near the surface to be uniform; the cavitation effect of ultrasound in the liquid can also suppress the corrosion process, facilitating surface brightening.

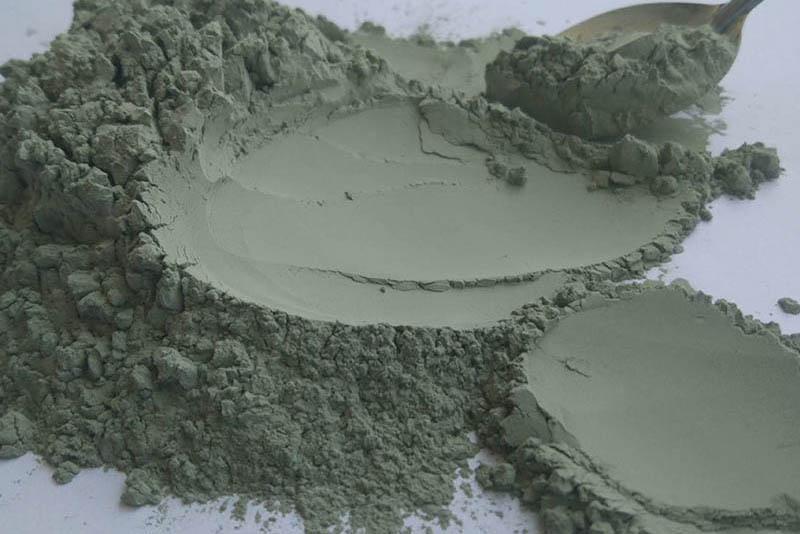

5. Fluid polishing: Fluid polishing relies on high-speed flowing liquids and the abrasive particles they carry to scour the surface of the workpiece to achieve polishing. Common methods include abrasive jet processing, liquid jet processing, and fluid dynamic grinding. Fluid dynamic grinding is driven by hydraulic power, causing the liquid medium carrying abrasive particles to flow back and forth at high speed over the surface of the workpiece. The medium mainly uses special compounds (polymeric substances) that flow well at lower pressures, mixed with abrasives, which can be silicon carbide powder.

6. Magnetic abrasive polishing: Magnetic abrasive polishing uses magnetic abrasives to form an abrasive brush under the action of a magnetic field to grind the workpiece. This method has high processing efficiency, good quality, easy control of processing conditions, and favorable working conditions. With suitable abrasives, the surface roughness can reach Ra0.1μm.

Previous:

Latest developments