In which fields is silicon carbide applied?

2025-01-08

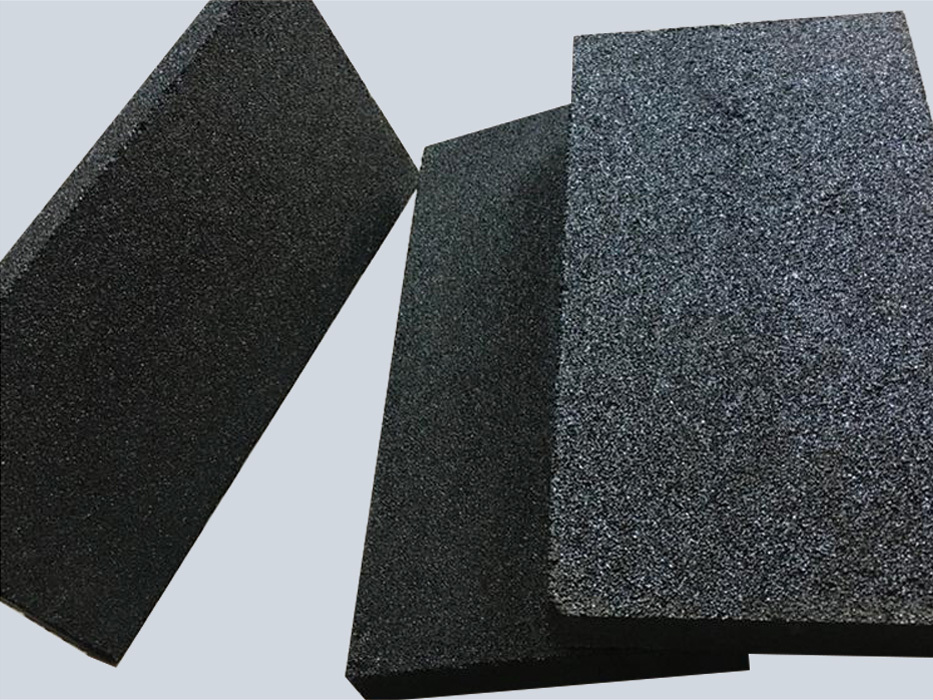

Silicon carbide, as a wide bandgap semiconductor material, shows extensive application potential in various fields due to its unique physical and chemical properties. This compound material composed of silicon and carbon has properties that lie between ceramics and metals, possessing various excellent physical and chemical characteristics.

The application of silicon carbide in the power device field is particularly prominent. Due to its high voltage resistance, low conduction resistance, and high frequency characteristics, silicon carbide has become an ideal choice for manufacturing high-performance power devices. These devices are widely used in electric vehicles, solar inverters, high-speed railway traction drives, and more. For example, the Tesla Model 3 uses an inverter equipped with SiC MOSFETs, improving energy efficiency and power density. In DC charging stations, SiC-based transistors can achieve higher switching frequencies, providing high power density and ultra-small size, accelerating the market penetration of silicon carbide in the fast charging field.

In the radio frequency device field, silicon carbide materials are used to manufacture high-performance radio frequency devices due to their high frequency characteristics. These devices play an important role in 5G communication, radar, satellite communication, and other fields. The high frequency characteristics of silicon carbide enable it to provide stable performance in these high-speed, high-frequency applications, meeting the demands of modern communication technology.

LED lighting is also an important area of application for silicon carbide. Silicon carbide-based LEDs have higher luminous efficiency and longer service life, suitable for indoor and outdoor lighting, displays, and more. As a raw material for making light-emitting diodes, silicon carbide can change the emission wavelength by adding different impurities, thus meeting the needs of different applications. This efficient LED lighting solution helps save energy and reduce emissions, improving energy utilization efficiency.

The application of silicon carbide in the electric vehicle field is also noteworthy. It is used to manufacture traction inverters for electric vehicles, improving energy efficiency and power density. This enables electric vehicles to have longer range and higher performance. With the growing global demand for new energy vehicles, the application prospects of silicon carbide in the electric vehicle field are broad.

In addition to the above fields, silicon carbide also shows significant advantages in high-temperature structural materials. Silicon carbide ceramic materials are used to manufacture high-temperature components for aerospace vehicles due to their high-temperature resistance and high strength characteristics. These components can maintain stable performance in extremely high-temperature environments, ensuring the safe operation of aerospace vehicles.

In the solar cell field, silicon carbide materials are used to manufacture substrates for solar cells, improving cell efficiency. The high thermal conductivity and chemical stability of silicon carbide make it an ideal substrate material for solar cells. As global demand for renewable energy grows, the application of silicon carbide in the solar cell field will continue to expand.

Silicon carbide is also used as linings for chemical equipment due to its corrosion resistance. It can work stably in various chemical media such as acids, bases, and salts, exhibiting good corrosion resistance. This gives silicon carbide a wide range of application prospects in the chemical industry.

In addition, silicon carbide ceramics are used to manufacture medical implants such as artificial joints due to their good biocompatibility. This biocompatibility gives silicon carbide materials unique advantages in the medical field, providing better solutions for patient recovery.

The production process of silicon carbide generates less waste, having a minimal impact on the environment, which aligns with sustainable development requirements. Its high efficiency and low energy consumption characteristics give it significant advantages in energy conversion and conservation. As global attention to environmental protection and sustainable development increases, the application of silicon carbide in these fields will also continue to grow.

The silicon carbide industry is rapidly developing, especially in the manufacturing of 8-inch wafers. Major global manufacturers are investing in expanding silicon carbide production capacity to meet the demand for silicon carbide materials in electric vehicles, industry, energy, and other fields. This trend will drive the further development of the silicon carbide industry and showcase its unique advantages and potential in more fields.

In summary, silicon carbide materials exhibit significant advantages in many fields due to their unique physical and chemical properties. They have wide applications in power devices, radio frequency devices, LED lighting, electric vehicles, high-temperature structural materials, solar cells, corrosion-resistant materials, and biocompatible materials. As global demand for high-performance materials and renewable energy grows, the application prospects of silicon carbide will be even broader.

Previous:

The next one:

Latest developments